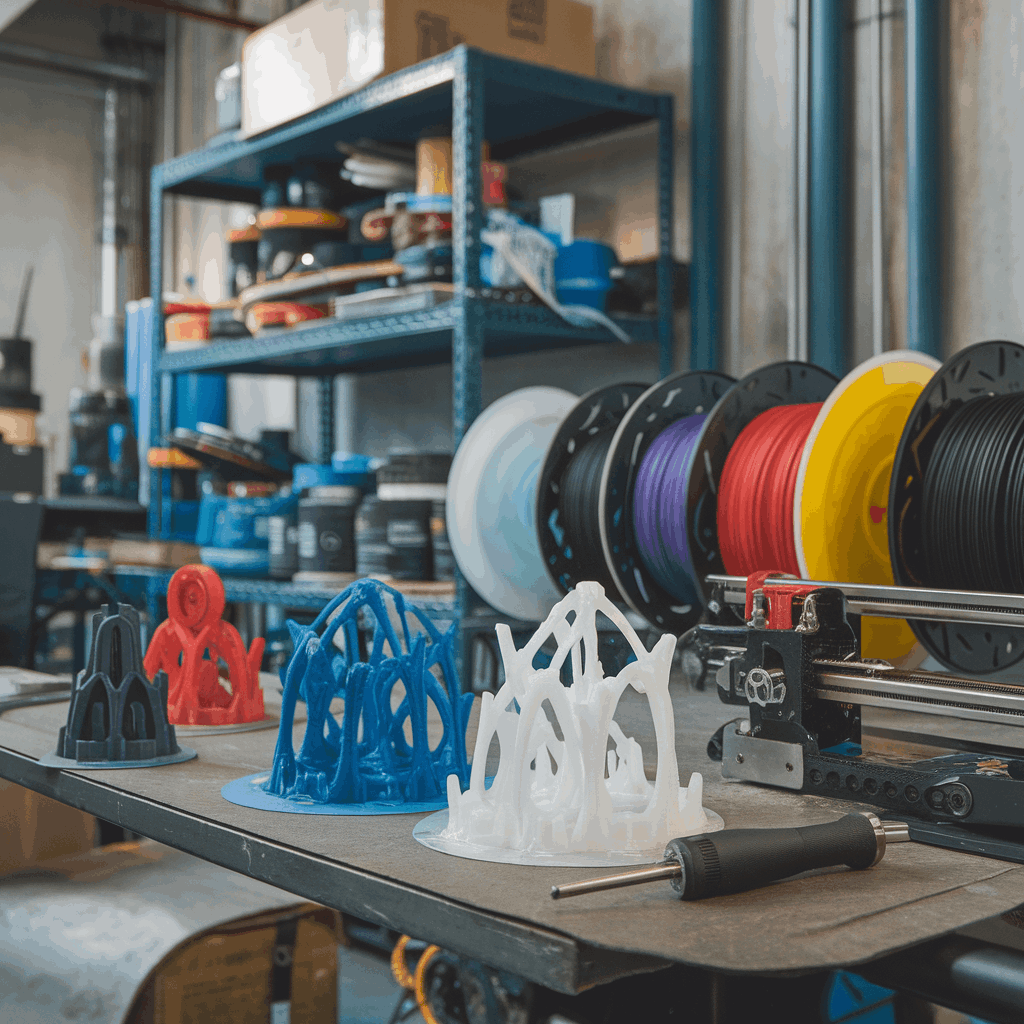

Structural Supports & Jigs

Breakaway and soluble support systems tailored to part geometry. Optimized density and thermal profiles reduce scarring and print time.

- Custom cut‑outs for airflow and access

- Material‑matched thermal expansion

- Assembly aids, nests, and fixtures